Home > Products > Rubber Extruder > Cold Feed Rubber Extruder > Rubber EPDM Plastic PVC TPE TPV Windows Door Sealing Strip Extruding Production Line

The application of sealing strips is very extensive, such as in cars, doors and windows, machinery, trunk lids, engine hoods, water tanks, emergency doors, etc., mainly playing a role in shock absorption, waterproofing, sound insulation, heat insulation, dust prevention, fixation, etc.

Qingdao Steady Machinery Co.,Ltd. is professional sealing strip machine line maker.

When it comes to sealing strips, we will think of their application in car parts such as doors, windows, bodies, seats, sunroofs, engine cases, and trunk, as well as their waterproof, sealing, sound insulation, dust prevention, antifreeze, shock absorption, and other functions. As a professional enterprise producing sealing strips, we not only delve into every process of mold design, structural manufacturing, processing, assembly, trial molding, trial production, and mass production, but also pay great attention to the design of the sealing strip mold. As sealing strips are applied in different parts of the car, they have different purposes and functions, so the structural design of the mold is also crucial.

The rubber sealing strip production line consists of rubber extruder → Vulcanizing Tunnel → cooling tunnel( can add chiller) → haul off machine → winding machine.

Sealing Strip ExtruMachine often use models:

| MODEL | XJD-50 | XJD-65 | XJD-75 | XJD-90 |

| SCREW DIAMETER(mm) | Ф50 | Ф65 | Ф75 | Ф90 |

| SCREW L/D RATIO of Rubber Extruder | 12:1 or 14:1 | 12:1 or 14:1 | 12:1 or 14:1 | 12:1 14:1 or 16:1 |

| SCREW ROTATION SPEED(r/min) | 7-73 | 6.7-70 | 6-60 | 6.7-60 |

| MAX. PRODUCTION CAPACITY(kg/h) | 60 | 120 | 180 | 350 |

| POWER(kw) | 11 | 22 | 37 | 55 |

| REDUCER | hardened reducer (square box shape) | hardened reducer (square box shape) | hardened reducer (square box shape) | hardened reducer (square box shape) |

| MACHINE WEIGHT(T) | 1.1 | 1.65 | 1.8 | 2.5 |

| Dimension(L×W×H)mm | 1550×1050 ×1500 | 1900×800 ×1500 | 2340×1150 ×1250 | 2300×1150 ×1400 |

The rubber sealing strip production line consists of rubber extruder → Vulcanizing Tunnel → cooling tunnel( can add chiller) → haul off machine → winding machine.

DETAIL IMAGES

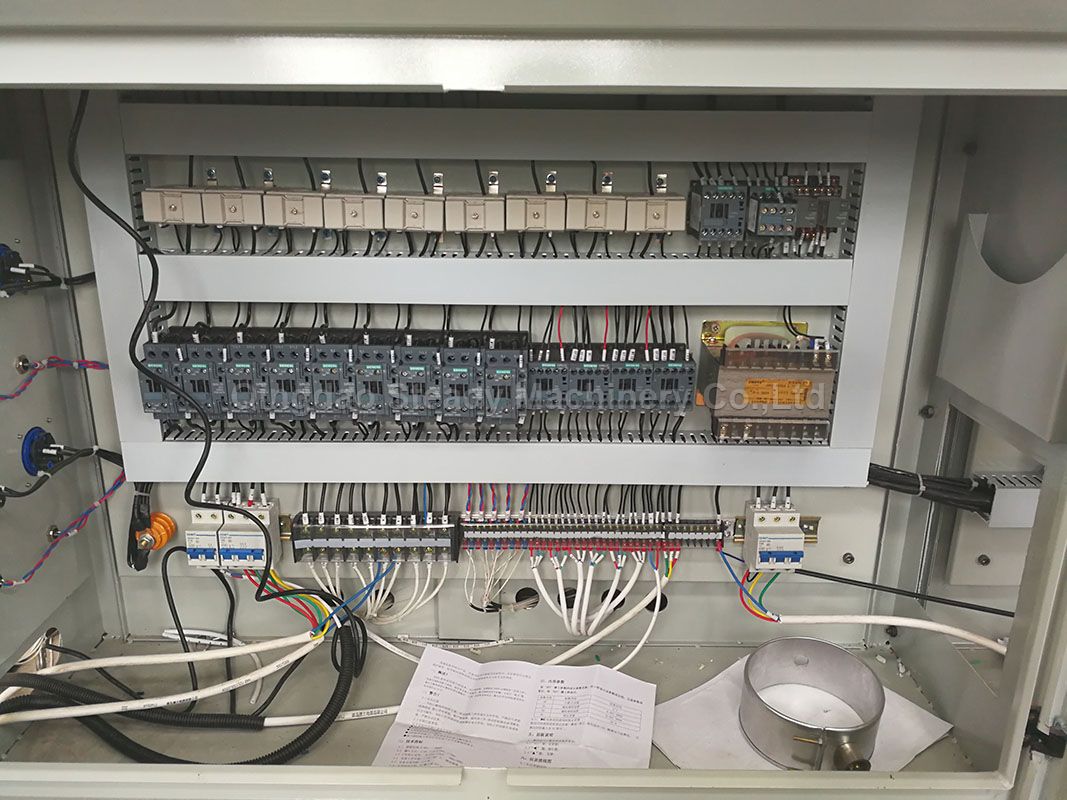

Control Box

Qingdao Steady Machinery's extruder adopts famous brand electronics, works accurate and stable

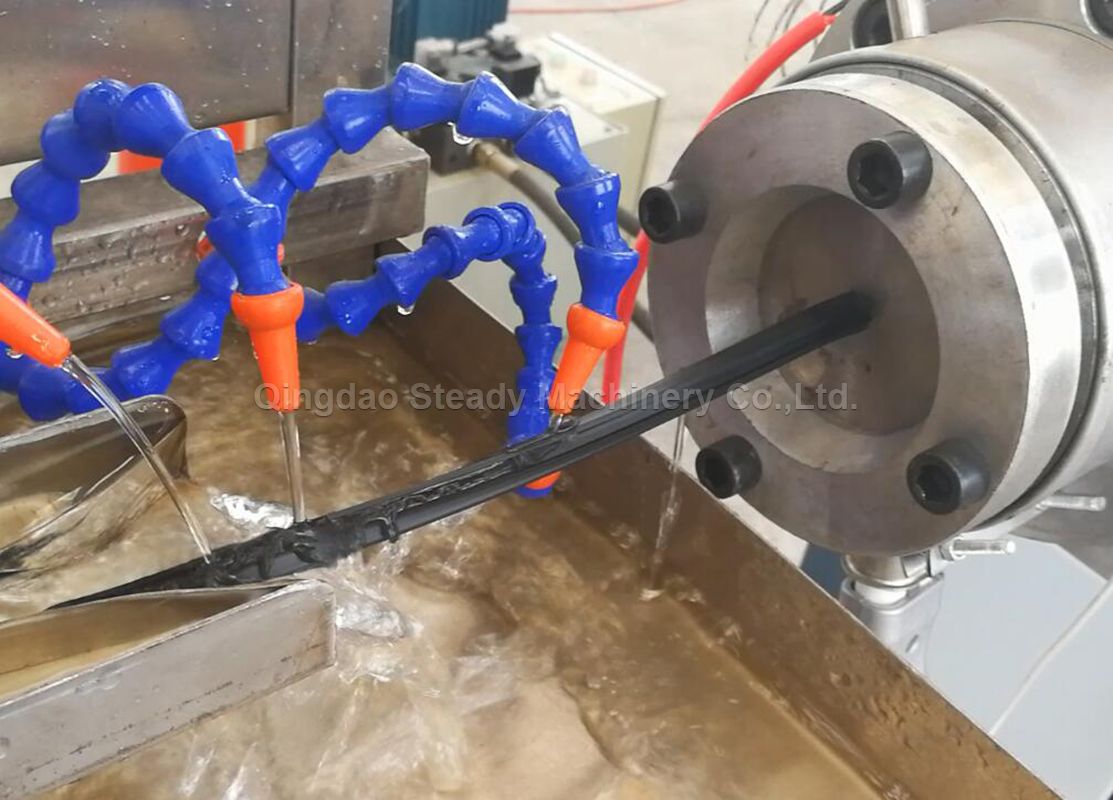

Barrel and Screws

Our Screw & Barrel Advantage is as below, ensures our machine 1.5 times more durable than other machines

The material is: 38CrMOALA

Temper Degree:HB240°~280°

Nitriding Hardness:HV850°~1000°

Nitriding Deepness:0.45~0.7mm

Nitriding Brittleness:≤Grade Ⅱ

Surface Roughness:Ra0.4

Screw Straightness:0.015mm

Hard Chrome Plating after Nitriding:≥900HV

Chrome Thickness:0.05~0.10mm

Two-phase Alloys:HRC56°~65°(nickel-base alloy)

Alloy Deepness:1.5~2.0mm

Screw and barrel processing:

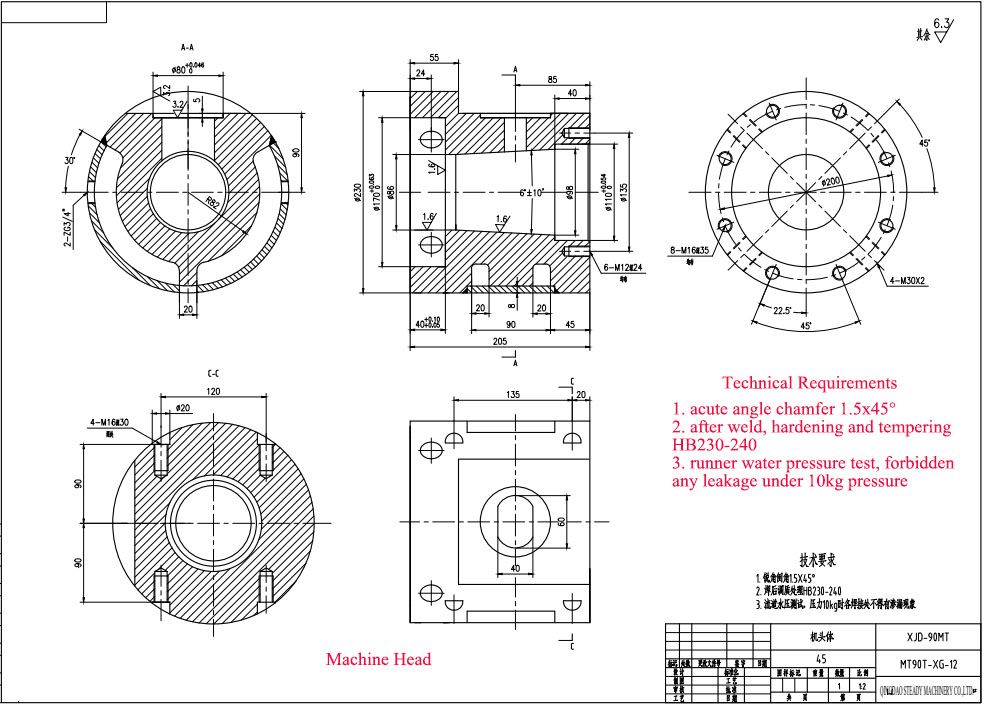

Machine Head

high quality steel, high precision machining

Machine Head Reference Picture

Mold

High quality extruding mold ensures high quality rubber products

Loading Into Container Export

Extruder Use and Maintenance

① The machine head should be assembled together and installed as a whole on the extruder.

② Before assembling the machine head, the grease applied during storage should be wiped off, and the surface of the mold cavity should be carefully checked for scratches, scratches, and rust spots. Necessary polishing should be carried out, and then a layer of silicone oil should be applied to the surface of the flow channel.

③ Assemble the various plates of the machine head in sequence, apply high-temperature grease to the threads of the bolts, and then tighten the bolts and flange.

④ Place the porous plate between the machine head flanges to ensure that it is tightly pressed without overflowing.

⑤ Before tightening the fastening bolts of the connecting flange between the machine head and the extruder, the horizontal position of the mouth mold should be adjusted. The square machine head can be horizontally adjusted, while the circular machine head should be leveled with the bottom surface of the machine head mouth mold based on the fixed model adhesive surface.

⑥ Tighten the connecting flange bolts, tighten the machine head fastening bolts, install the heating ring and thermocouple, and ensure that the heating ring is tightly attached to the outer surface of the machine head.

⑦ Install the set sleeve and adjust it in place. Check if the center line of the host, set sleeve, and traction machine is aligned. After adjustment, tighten the fixing bolts. Connect all water pipes and vacuum pipes of the set sleeve.

⑧ Turn on the heating power and evenly heat the machine head and machine casing. At the same time, open the cooling water at the bottom of the feeding hopper and the gearbox, as well as the inlet valve of the exhaust vacuum pump. When heating, adjust the temperature of each section to 140 ℃ first, and hold it for 30-40 minutes when the temperature rises to 140 ℃. Then, raise the temperature to the normal production temperature.

Plastic sealing strip profuction line often use TPE,. TPV or PVC as raw material.

The plastic sealing strip production line consists of plastic extruder → cooling tunnel( with chiller) → haul off machine → winding machine.

Sealing Strip Machine often use models:

| MODEL | XJD-50 | XJD-65 | XJD-75 | XJD-90 |

| SCREW DIAMETER(mm) | Ф50 | Ф65 | Ф75 | Ф90 |

| SCREW L/D RATIO of Plastic Extruder | 1:30 | 1:30 | 1:30 | 1:30 |

| SCREW ROTATION SPEED(r/min) | 7-73 | 6.7-70 | 6-60 | 6.7-60 |

| MAX. PRODUCTION CAPACITY(kg/h) | 60 | 120 | 180 | 350 |

| POWER(kw) | 11 | 22 | 37 | 55 |

| REDUCER | hardened reducer (square box shape) | hardened reducer (square box shape) | hardened reducer (square box shape) | hardened reducer (square box shape) |

| MACHINE WEIGHT(T) | 1.1 | 1.65 | 1.8 | 2.5 |

| Dimension(L×W×H)mm | 1550×1050 ×1500 | 1900×800 ×1500 | 2340×1150 ×1250 | 2300×1150 ×1400 |

DETAIL IMAGES

Control Box

Qingdao Steady Machinery's extruder adopts famous brand electronics, works accurate and stable

Barrel and Screws

Our Screw & Barrel Advantage is as below, ensures our machine 1.5 times more durable than other machines

The material is: 38CrMOALA

Temper Degree:HB240°~280°

Nitriding Hardness:HV850°~1000°

Nitriding Deepness:0.45~0.7mm

Nitriding Brittleness:≤Grade Ⅱ

Surface Roughness:Ra0.4

Screw Straightness:0.015mm

Hard Chrome Plating after Nitriding:≥900HV

Chrome Thickness:0.05~0.10mm

Two-phase Alloys:HRC56°~65°(nickel-base alloy)

Alloy Deepness:1.5~2.0mm

Screw and barrel processing:

Machine Head

high quality steel, high precision machining

Machine Head Reference Picture

Mold

High quality extruding mold ensures high quality rubber products

Loading Into Container Export

Assist machines

Hydraulic Screen Changer

Stainless Steel Cooling Water Tunnel

Chiller

Haul Off Machine/Caterpillar with meter counter

Sealing Strip Winding Machine

Extruder Line Use and Maintenance

① The machine head should be assembled together and installed as a whole on the extruder.

② Before assembling the machine head, the grease applied during storage should be wiped off, and the surface of the mold cavity should be carefully checked for scratches, scratches, and rust spots. Necessary polishing should be carried out, and then a layer of silicone oil should be applied to the surface of the flow channel.

③ Assemble the various plates of the machine head in sequence, apply high-temperature grease to the threads of the bolts, and then tighten the bolts and flange.

④ Place the porous plate between the machine head flanges to ensure that it is tightly pressed without overflowing.

⑤ Before tightening the fastening bolts of the connecting flange between the machine head and the extruder, the horizontal position of the mouth mold should be adjusted. The square machine head can be horizontally adjusted, while the circular machine head should be leveled with the bottom surface of the machine head mouth mold based on the fixed model adhesive surface.

⑥ Tighten the connecting flange bolts, tighten the machine head fastening bolts, install the heating ring and thermocouple, and ensure that the heating ring is tightly attached to the outer surface of the machine head.

⑦ Install the set sleeve and adjust it in place. Check if the center line of the host, set sleeve, and traction machine is aligned. After adjustment, tighten the fixing bolts. Connect all water pipes and vacuum pipes of the set sleeve.

⑧ Turn on the heating power and evenly heat the machine head and machine casing. At the same time, open the cooling water at the bottom of the feeding hopper and the gearbox, as well as the inlet valve of the exhaust vacuum pump. When heating, adjust the temperature of each section to 140 ℃ first, and hold it for 30-40 minutes when the temperature rises to 140 ℃. Then, raise the temperature to the normal production temperature.

Ø1. Will your machine meet our voltage, can we use your machine in our country?

Yes, we can customize every aspect of the machine according to customers’ work needs, Voltage,

Electricity frequency, clamping force, (heating )platen size, daylight, piston travel, working layer number, with sliding platen or not, assist cylinder, Control method, automatization level, PLC or not, etc,

Ø 2. Guarantee?

For the whole machine, not less than 2 years quality guarantee, and life long technical service whenever it’s needed.

Ø 3. Will the machine be kept well while on the sea journey?

Yes, for small size or single set machine, we use good quality fumigation free ply wood making strong packing for them.

For big size machine or multi sets small size machine, after proper treatment, we fixed them in the container so that the machine won’t get rust or damage in the sea voyage.

Ø 4. Whats’ the payment method?

There are TT, L/C, Credit Card, Western Union, Paypal, Alipay etc.

Ø5. What’s the shipping method?

Our rubber machines are most often shipped by sea, but for land-locked state, there are train or truck transportation. Or there are joint transportation between land and water.

When it come to small pare parts, it’s by international courier by air.

Look forward to hearing from you

Welcome friends and customers domestic and abroad to cooperate sincerely and create brilliance together!

Copyright © Qingdao Steady Machinery Co.,Ltd. All Rights Reserved |

Sitemap

| Powered by